- Home

- Company

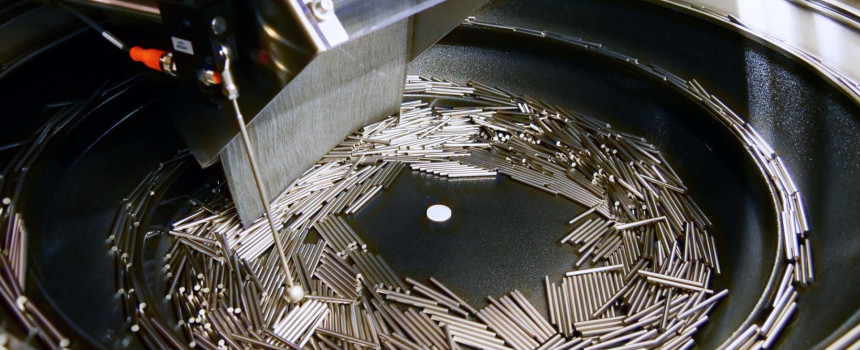

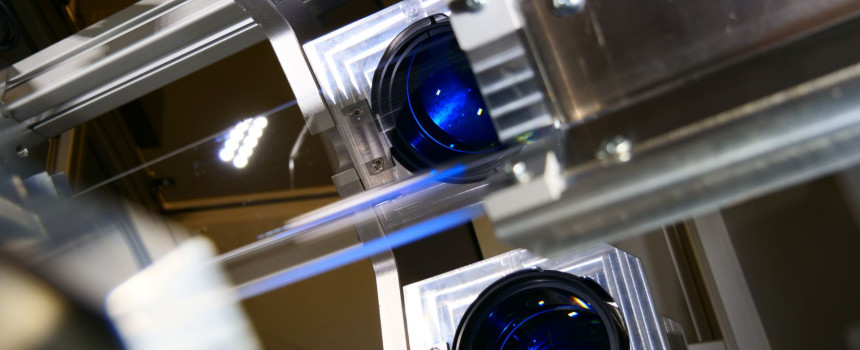

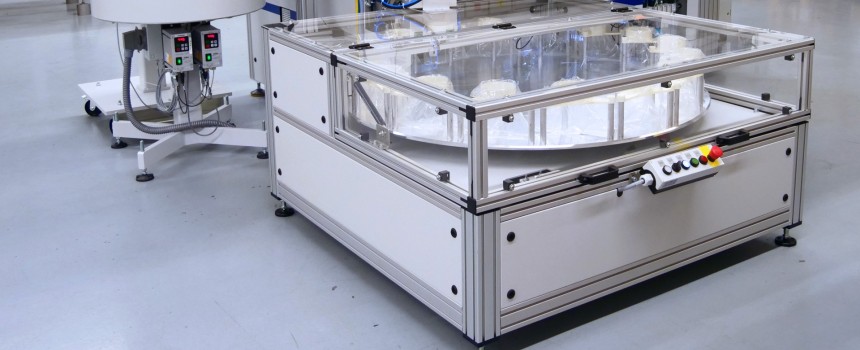

- Vision Inspection Systems

- Printing Plate Automation

- Service

- Careers

- Job offers

- Vertriebsingenieur (m/w/d) für Industrial Vision Automation

- Inside Sales Engineer (m/w/d) Industrial Vision Automation

- Entwicklungsingenieur/Techniker (m/w/d) in der Konstruktion

- Mechatroniker/Industriemechaniker (m/w/d) zur Mitarbeit und als Ausbilder

- Inbetriebnahmemonteur / Techniker (m/w/d)

- Mechatroniker (m/w/d)

- Servicetechniker (m/w/d) im Außendienst

- Training at Nela

- Job offers

- News